Introduction

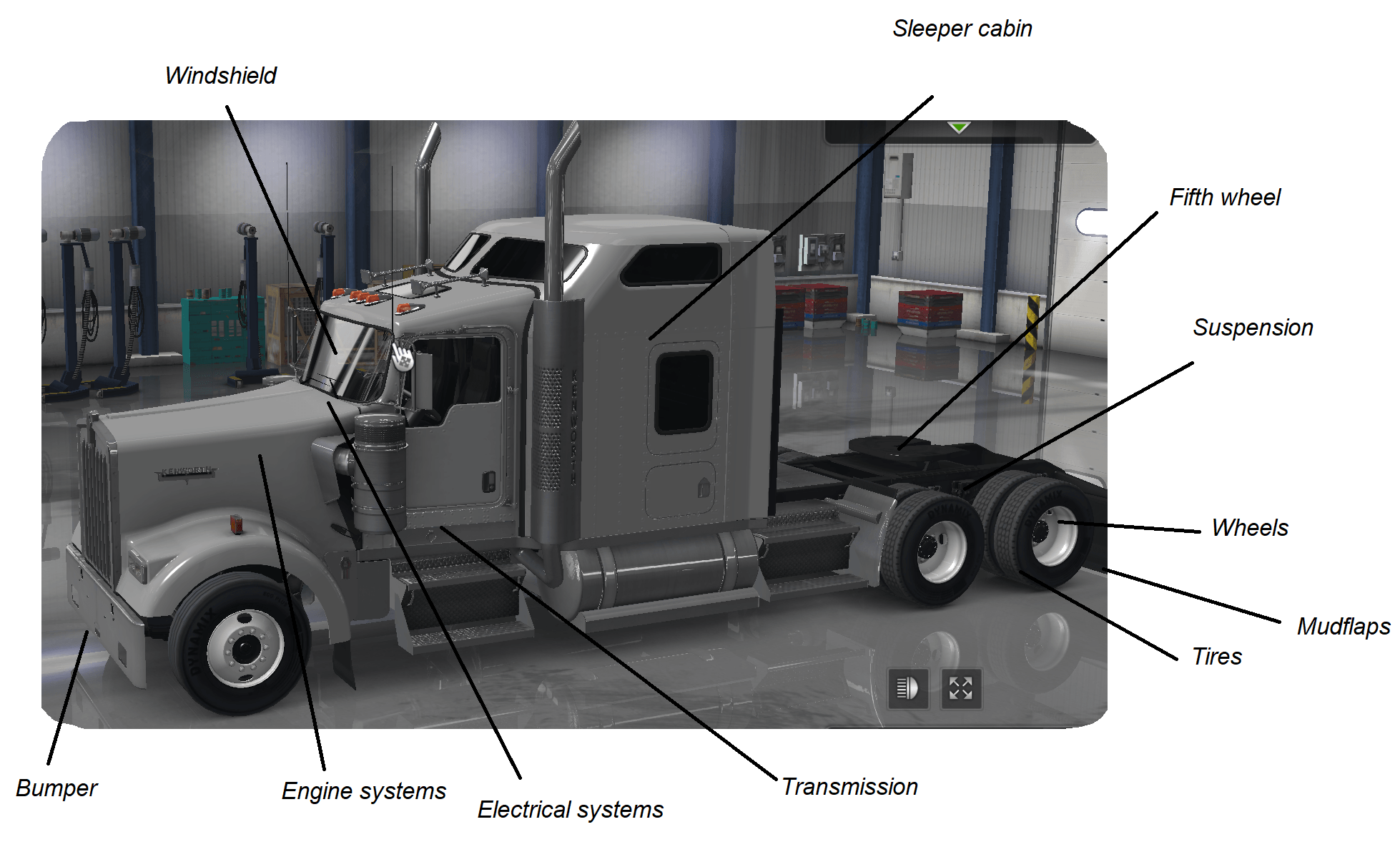

Semi-trucks, the workhorses of the American economy, are complex machines comprised of thousands of individual parts working in harmony. Understanding the names of these parts is crucial for anyone involved in the trucking industry, whether you're a driver, mechanic, dispatcher, fleet manager, or simply someone interested in these massive vehicles. This knowledge facilitates clear communication during maintenance, repairs, and ordering, preventing costly misunderstandings and downtime. This article serves as a comprehensive guide to semi-truck part names, covering key components, their functions, and related terminology.

Semi Truck Part Names: A Comprehensive Guide

I. The Engine: The Heart of the Beast

The engine is arguably the most critical component of any semi-truck. It's responsible for generating the power that propels the vehicle and its heavy loads. Here's a breakdown of some essential engine parts:

- Engine Block: The foundational structure of the engine, containing the cylinders.

- Cylinder Head: Sits atop the engine block, housing the valves, spark plugs (in gasoline engines), and fuel injectors.

- Pistons: Move up and down within the cylinders, converting combustion pressure into mechanical energy.

- Connecting Rods: Connect the pistons to the crankshaft.

- Crankshaft: Converts the reciprocating motion of the pistons into rotary motion, which drives the drivetrain.

- Camshaft: Controls the opening and closing of the intake and exhaust valves.

- Valves (Intake & Exhaust): Regulate the flow of air and fuel into the cylinders and exhaust gases out.

- Turbocharger (or Supercharger): Forces more air into the engine, increasing power output.

- Fuel Injectors: Atomize and inject fuel into the cylinders.

- Fuel Pump: Supplies fuel to the fuel injectors.

- Oil Pump: Circulates oil throughout the engine for lubrication and cooling.

- Water Pump: Circulates coolant to regulate engine temperature.

- Radiator: Dissipates heat from the coolant.

- Thermostat: Regulates coolant flow to maintain optimal engine temperature.

- Air Filter: Cleans the air entering the engine, preventing damage.

- Fuel Filter: Cleans the fuel before it reaches the engine.

- Oil Filter: Removes contaminants from the engine oil.

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Muffler: Reduces exhaust noise.

- Diesel Particulate Filter (DPF): Captures particulate matter from diesel exhaust.

- Selective Catalytic Reduction (SCR) System: Reduces nitrogen oxide (NOx) emissions.

- Engine Control Module (ECM): The engine's computer, controlling various engine functions.

II. The Drivetrain: Transferring Power to the Wheels

The drivetrain is responsible for transmitting power from the engine to the wheels. Key components include:

- Clutch: Connects and disconnects the engine from the transmission, allowing for gear changes.

- Transmission: Provides different gear ratios to optimize engine performance for varying speeds and loads.

- Driveshaft: Transmits power from the transmission to the rear axle(s).

- Differential: Allows the wheels on an axle to rotate at different speeds, essential for turning.

- Axle Shafts: Transmit power from the differential to the wheels.

- Universal Joints (U-Joints): Allow the driveshaft to flex as the suspension moves.

- Wheel Hubs: Connect the wheels to the axle.

- Wheel Bearings: Allow the wheels to rotate smoothly on the axle.

III. The Braking System: Ensuring Safe Stops

A reliable braking system is paramount for semi-truck safety.

- Air Compressor: Compresses air to power the braking system.

- Air Tanks: Store compressed air for use by the brakes.

- Brake Valves: Control the flow of compressed air to the brake chambers.

- Brake Chambers: Convert air pressure into mechanical force to apply the brakes.

- Slack Adjusters: Adjust the distance between the brake shoes and the brake drum.

- Brake Drums (or Rotors): The rotating surfaces against which the brake shoes (or pads) press to slow or stop the vehicle.

- Brake Shoes (or Pads): The friction materials that press against the brake drums (or rotors) to slow or stop the vehicle.

- Anti-lock Braking System (ABS): Prevents the wheels from locking up during braking, improving control.

- Automatic Slack Adjusters (ASA): Automatically maintain proper brake adjustment.

IV. The Suspension System: Providing a Smooth Ride

The suspension system absorbs shocks and vibrations, providing a comfortable ride and maintaining vehicle stability.

- Leaf Springs: Stacked layers of steel that support the vehicle's weight and absorb shocks.

- Air Springs: Inflatable bags that provide a smoother ride than leaf springs.

- Shock Absorbers: Dampen the oscillations of the springs, preventing excessive bouncing.

- Kingpins: Connect the front axle to the steering knuckles.

- Tie Rods: Connect the steering linkage to the steering knuckles.

- Steering Knuckles: Pivot to allow the wheels to steer.

V. The Electrical System: Powering the Truck's Functionality

The electrical system powers various components, including lights, sensors, and the engine control module.

- Batteries: Store electrical energy.

- Alternator: Charges the batteries while the engine is running.

- Starter Motor: Cranks the engine to start it.

- Wiring Harness: A network of wires that connects the various electrical components.

- Fuses and Circuit Breakers: Protect the electrical system from overloads.

- Lights (Headlights, Taillights, Brake Lights, Turn Signals): Provide visibility and signaling.

- Sensors (ABS Sensors, Engine Sensors, etc.): Monitor various system parameters and provide data to the ECM.

VI. The Cab and Chassis: Structure and Comfort

- Cab: The compartment where the driver sits.

- Chassis: The frame of the truck.

- Fifth Wheel: The coupling device that connects the tractor to the trailer.

- Fuel Tanks: Store fuel for the engine.

- Wheels and Tires: Provide traction and support the vehicle's weight.

- Mud Flaps: Prevent debris from being thrown up by the tires.

- Mirrors (Side Mirrors, Rearview Mirror): Provide visibility.

VII. The Trailer Components

- Landing Gear: Supports the trailer when it is not connected to the tractor.

- Trailer Axles: Support the weight of the trailer.

- Trailer Brakes: Slow down and stop the trailer.

- Trailer Lights: Provide visibility and signaling.

- Kingpin: Connects the trailer to the fifth wheel of the tractor.

Practical Advice and Actionable Insights

- Familiarize yourself with the parts manual: Every truck has a parts manual. Use it!

- Use the correct terminology: Accurate communication saves time and money.

- Invest in quality parts: Cheaper parts may fail sooner, leading to more downtime.

- Keep detailed maintenance records: Track repairs and replacements to identify potential problems.

Table Price

| Part Name | Average Price Range | Notes |

|---|---|---|

| Engine Block | $5,000 - $15,000 | Price varies significantly based on engine type and manufacturer. |

| Cylinder Head | $1,000 - $5,000 | Can be reconditioned or replaced. |

| Turbocharger | $800 - $3,000 | Performance upgrades available at higher prices. |

| Fuel Injector (each) | $100 - $500 | Typically replaced in sets. |

| Air Compressor | $500 - $2,000 | Varies based on CFM (cubic feet per minute) output. |

| Brake Chamber | $50 - $200 | Replace in pairs for optimal braking. |

| Leaf Spring | $200 - $800 | Price depends on length and capacity. |

| Air Spring | $100 - $500 | Offers a smoother ride. |

| Fifth Wheel | $800 - $3,000 | Choose a model rated for your typical load. |

| Tire (each) | $300 - $800 | Price varies based on size, ply rating, and brand. |

| Diesel Particulate Filter (DPF) | $2,000 - $5,000 | Requires periodic cleaning or replacement. |

| Selective Catalytic Reduction (SCR) | $3,000 - $8,000 | System |

Potential Challenges and Solutions

- Challenge: Difficulty identifying parts due to wear and tear.

- Solution: Consult a parts specialist or use VIN (Vehicle Identification Number) lookup tools.

- Challenge: Finding reliable suppliers.

- Solution: Research suppliers, read reviews, and ask for recommendations.

- Challenge: High cost of parts.

- Solution: Consider remanufactured or used parts from reputable sources.

- Challenge: Counterfeit parts.

- Solution: Purchase parts from authorized dealers or trusted suppliers.

Conclusion

A thorough understanding of semi-truck part names is an invaluable asset in the trucking industry. It empowers drivers, mechanics, and fleet managers to communicate effectively, diagnose problems accurately, and ensure the safe and efficient operation of these vital vehicles. By familiarizing yourself with the components discussed in this guide, you'll be well-equipped to navigate the complexities of semi-truck maintenance and repair. Remember to always prioritize quality and safety when selecting and replacing parts, and don't hesitate to seek professional assistance when needed.

Frequently Asked Questions (FAQ)

- Q: Where can I find the part number for a specific component?

- A: The part number is typically stamped on the part itself or listed in the truck's parts manual.

- Q: Are aftermarket parts as good as OEM (Original Equipment Manufacturer) parts?

- A: Some aftermarket parts are of excellent quality, but it's essential to research the manufacturer and read reviews before purchasing.

- Q: How often should I replace certain parts, like air filters or fuel filters?

- A: Refer to the truck's maintenance schedule for recommended replacement intervals.

- Q: What is the difference between a "day cab" and a "sleeper cab"?

- A: A day cab is a shorter cab without sleeping accommodations, while a sleeper cab has a sleeping compartment for long-haul drivers.

- Q: Can I diagnose engine problems myself?

- A: Some basic diagnostic procedures can be performed by experienced individuals, but complex issues should be addressed by a qualified mechanic.

0 comments